Stress-strain curves for different types of materials

The stress-strain curve is resulted from tensile, compression and bending tests. The universal tensile testing machine is able to perform tensile, compression, bending tests and draw stress-strain curves of different materials. We describe Hooke’s law, the stress-strain curve of steel, glass, rubber, wire, and elastic and plastic areas in soft and brittle materials.

What is stress-strain curve?

The relationship between stress and strain, which each material shows, can be seen through the stress-strain curve. This curve is unique for each material and it is obtained by recording the change in length (strain) of a specific material per tensile or compressive force (tension) at specific intervals

Hook's law

According to Hooke’s law, stress is directly proportional to strain. But this is true only up to a point, and after this point, with increasing stress, we find out that the stress is not proportional to the strain

Here, we will examine the stress-strain curve. We will also see different types of materials and their elastic properties

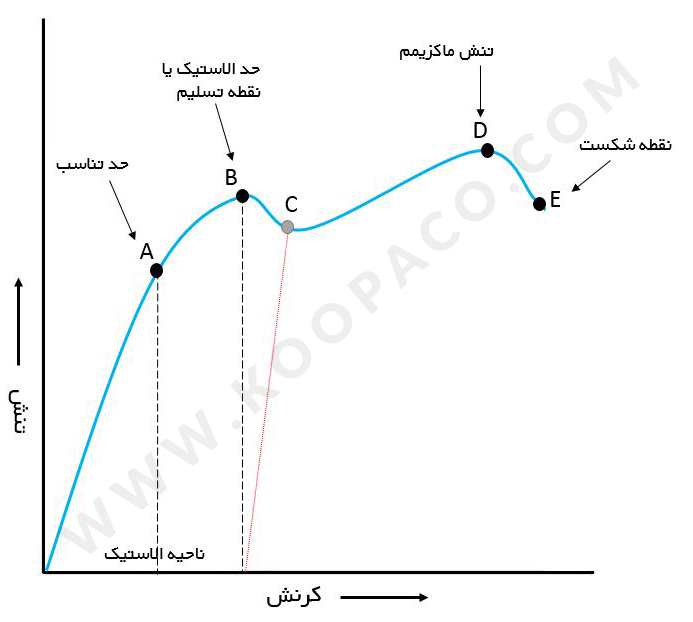

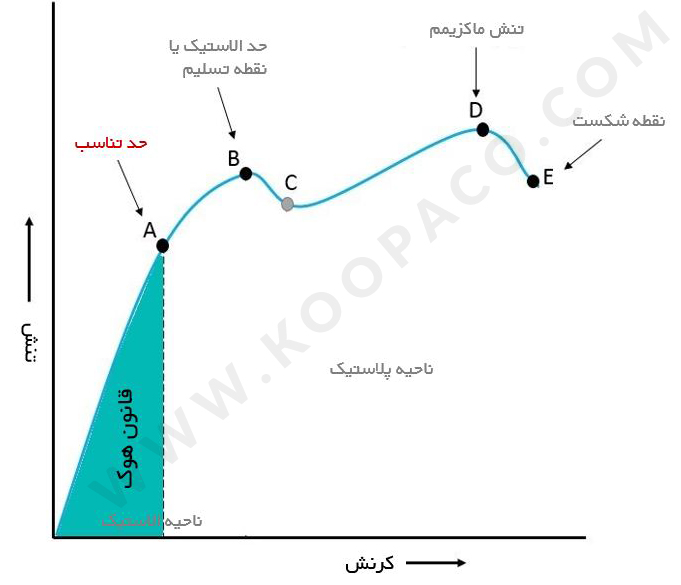

Stress-strain curve analysis

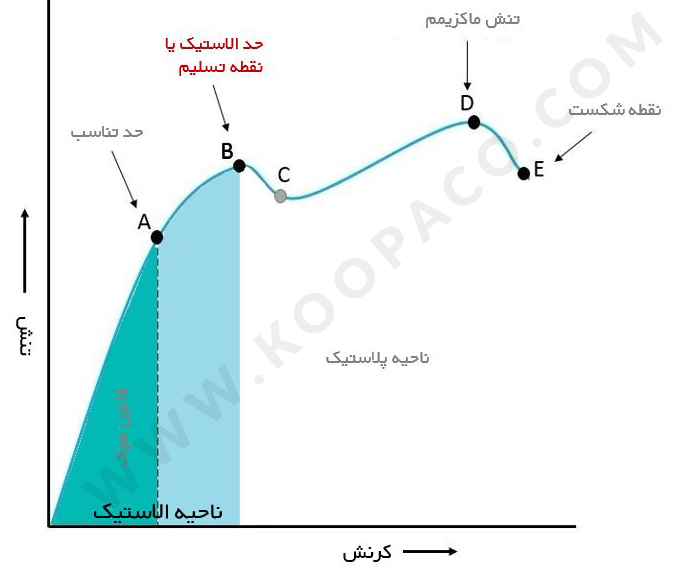

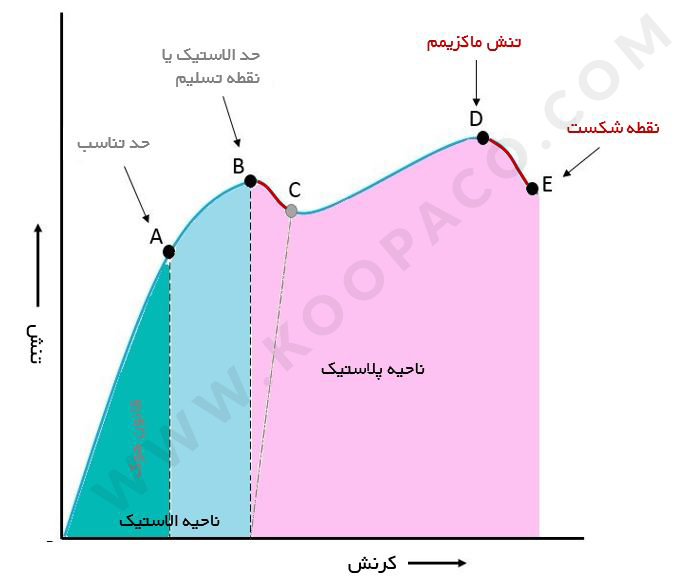

In this part of the diagram (according to Figure 2), materials follow Hooke’s law, and strain is directly proportional to stress, and if the stress is removed, the material returns to its original state

In AB (Figure 3), we see that material does not obey Hooke’s law. It means strain is not proportional to stress. However, the material is still elastic in this area, which means that if we remove the stress, the material will return to its original shape. Point B is known as the elastic limit or yield point. Point C is in the plastic zone, which means that if the stress is removed here, the material will not return to its original shape. We observe a permanent deformation in material.

In BC and DE section(Figure 4), the material is in the plastic area. It means that the shape of the material changes . And we see that small changes in stress cause large deformations or strain. Point D is the maximum stress and E is the fracture point. Between D and E, it is observed that although the stress decreases, but the strain increases, and also between D and E, the material flows like a viscous.

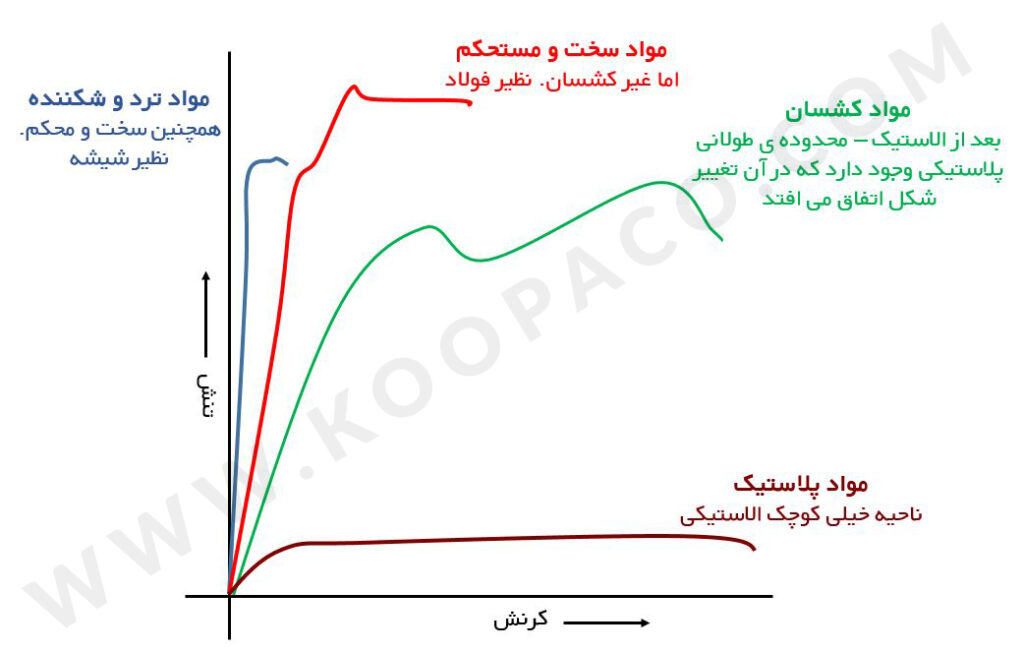

The stress-strain curve of some materials is shown as follows.

Glass is brittle and strong enough to withstand high stress without deforming. But it has a small plastic area that breaks easily without any deformation if stress is applied after this point.

Steel is strong and has a large elastic area and can be used to build bridges etc. But it has a small plastic area and therefore should not be used to make wires because it breaks easily.

However, ductile or elastic materials have a long plastic zone, and for this reason, it is possible to change their shape a lot or to use them by stretching them to produce wire.

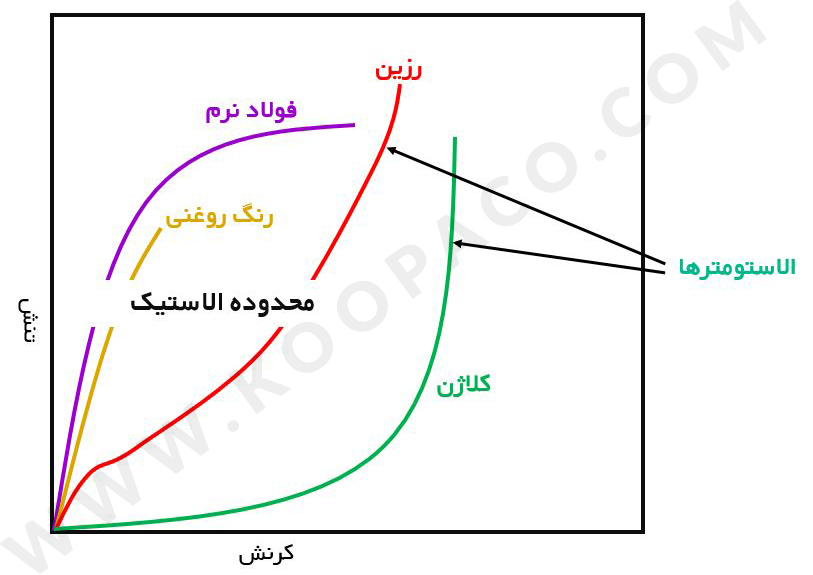

Elastomer

Elastomer is special material whose stress-strain curve is not a straight line even in the elastic area. Stress increases more than strain. Soft materials have no plastic area at all. The breaking point is just near the elastic limit. Rubber is an example of such a material. This material can be stretched several times its length and still return to its original size. Because they have a large elastic area and no plastic area.

In our body, elastic tissues, heart and collagen fibers are examples of elastomer materials.

You deserve to have the best and newest Universal Testing Machine

The best choice is KOOPA Universal testing machine, because this Universal testing machine is really professional, user-friendly, fully automatic and in accordance with modern design standards, and has high accuracy and reliability. The device is capable to install different load cells. Moreover, it has the bending equipment which can be easily installed on grips and run bending tests.

To see more information about Universal Testing Machine, click here

Selling all kinds of material testing equipment

To get more information, our expert consultants are ready to answer your questions.

Texture analyzer probes

- Penetration Probes of Texture Analyzer

- Knife Blade Probe of Texture Analyzer

- Cutting Wire Probe of Texture Analyzer

- Cylinder Probes of Texture Analyzer

- Spherical Probes of Texture Analyzer

You may like these articles too

«You could have the newest and most accurate material properties testers»

«KOOPA is the best choice for equipping the laboratory. Because KOOPA’s products are professional, user-friendly, fully automatic and in accordance with modern design standards and have high accuracy and reliability»

Resources

- koopaco.com

- ametektest.com