Features

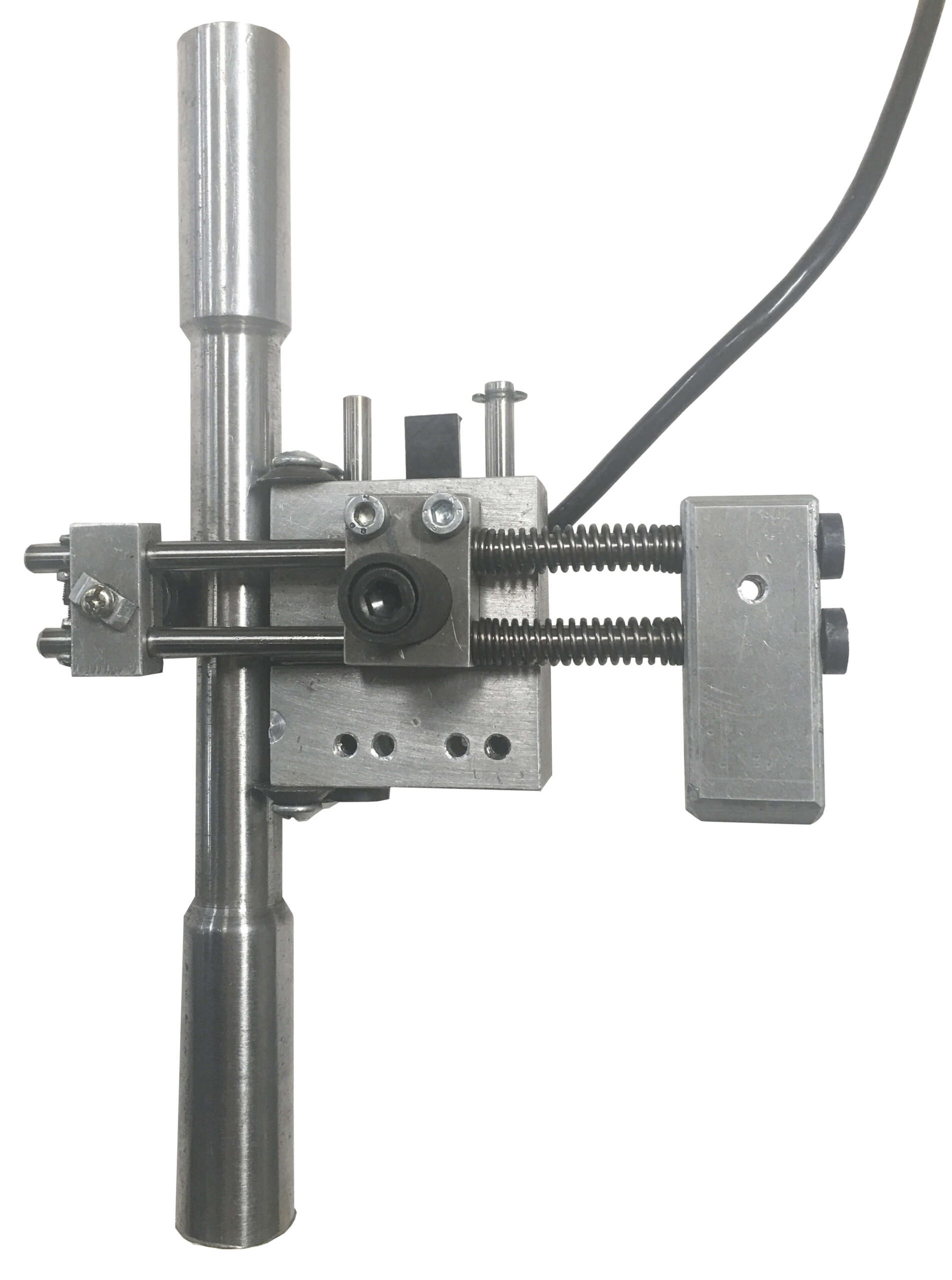

- Simple and accurate adjustment of the distance between the supports using a ruler and a marker

- Interchangeable supports with different radius

- Capabile to addjust the distance between the supports

- With the capacity of 500 k

TK100-500 bending fixture is one of the accessories of the following universal testing devices:

- Universal Testing Machine TB20

- Universal Testing Machine TB200

- Universal Testing Machine TB500

- Universal Testing Machine TB1000

- Universal Testing Machine TB3000

The base has two movable blocks on which a V-groove is considered for mounting different cylinders. The specimen is placed on these two supports. Standard fixture cylinders are 20mm in diameter and other sizes are available as well. There is a ruler on the base, which is used to measure the distance between two supports. The fixture base is installed directly on the grips of the Universal Testing Machine by the corresponding screws, and there is no need to open the grips.

Force is applied by a loading pin. The standard diameter of the cylinder is 20mm and other sizes can be prepared.

The three-point bending test provides the values of the bending elasticity coefficient Ef, bending stress δf, bending strain δf and the bending stress-strain response of the material. The main advantage of the three-point bending test is the ease of sample preparation and testing. However, this method also has disadvantages: the results of this test method are sensitive to the sample and loading method and pressure application rate.